Over 100 MILLION Square Feet of Tarps and Buildings Manufactured!

ABOUT US

MANUFACTURED, ENGINEERED AND SERVICED LOCALLY

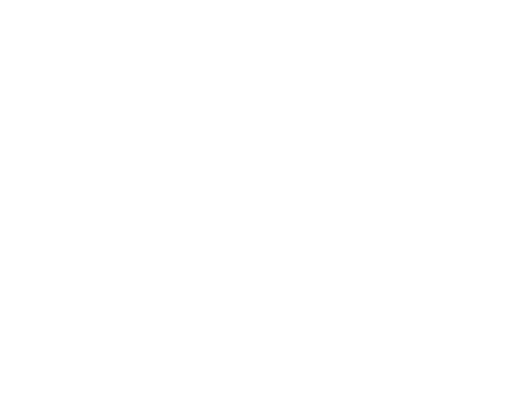

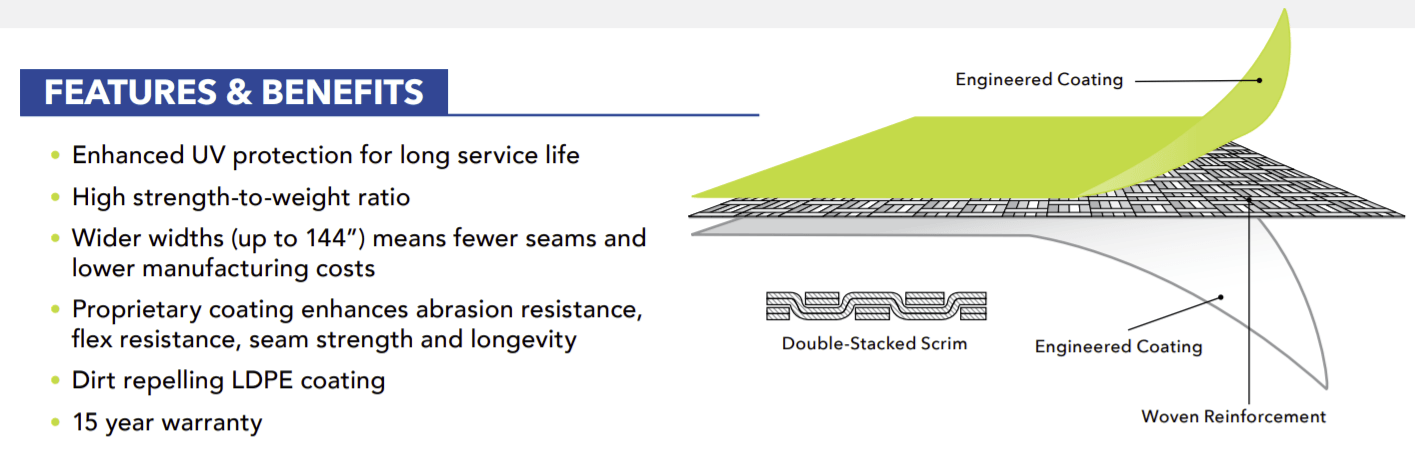

STRUCTURE FABRIC

Performance Beyond Expectations - Avalanche Structure Fabric designed with Snow Removal and Extreme Cold Weather in mind. The non-stick lacquer finish is so slippery that when snow slides off the roof with ease it literally looks like an Avalanche. Avalanche Structure Fabric is made from weft inserted high tenacity polyester thermally knife coated with Poly Vinyl Chloride (PVC). Decades of engineering and field testing went into the manufacturing process to ensure Maximum Seam Strength, UV Longevity, Fire Safety and Cold Weather Performance. Avalanche Structure Fabric is the First Choice for Structure Performance.

Avalanche Structure Fabric advantages include:

- 15 Year Warranty.

- Advanced PVDF Lacquer for a Non-Stick Surface and Extended UV Weathering.

- Thermally Coated PVC in 18oz, 20oz or 22oz (will depend on building size and application).

- Extreme Cold Weather Pliability.

- Heat Cured for Exceptional Seam Strength.

Avalanche Structure Fabric Specifications:

- 1000 x 1000 Denier Filament.

- Virgin PVC Coating

- PVDF Lacquer Finish

- Cold Crack ASTM D2136, no cold crack or flaking at -45°C (-49°F)

- Fire Retardant

- NFPA 701- 2010 Test Method 1 & 2

- CAN/ULC-S109-14

- California Fire Marshal Title 19 Section 1273.3

- Range of colors

- Industry leading warranties

- Improved fungal resistance

- Engineered coatings provide exceptional performance properties

- Technologically designed to stand up to some of the most demanding weather conditions

- California Fire Marshall

- ASTM E84 (Class 1)

- NFPA 701 (Large and Small Scale)

- CAN/ULC S-109 (Large and Small Scale)

- UBC31-1

- FAR 25.863(a) Appendix F, Part 1

- EN13501.1 (B.s1.d0)

- DIN4102 (B1)

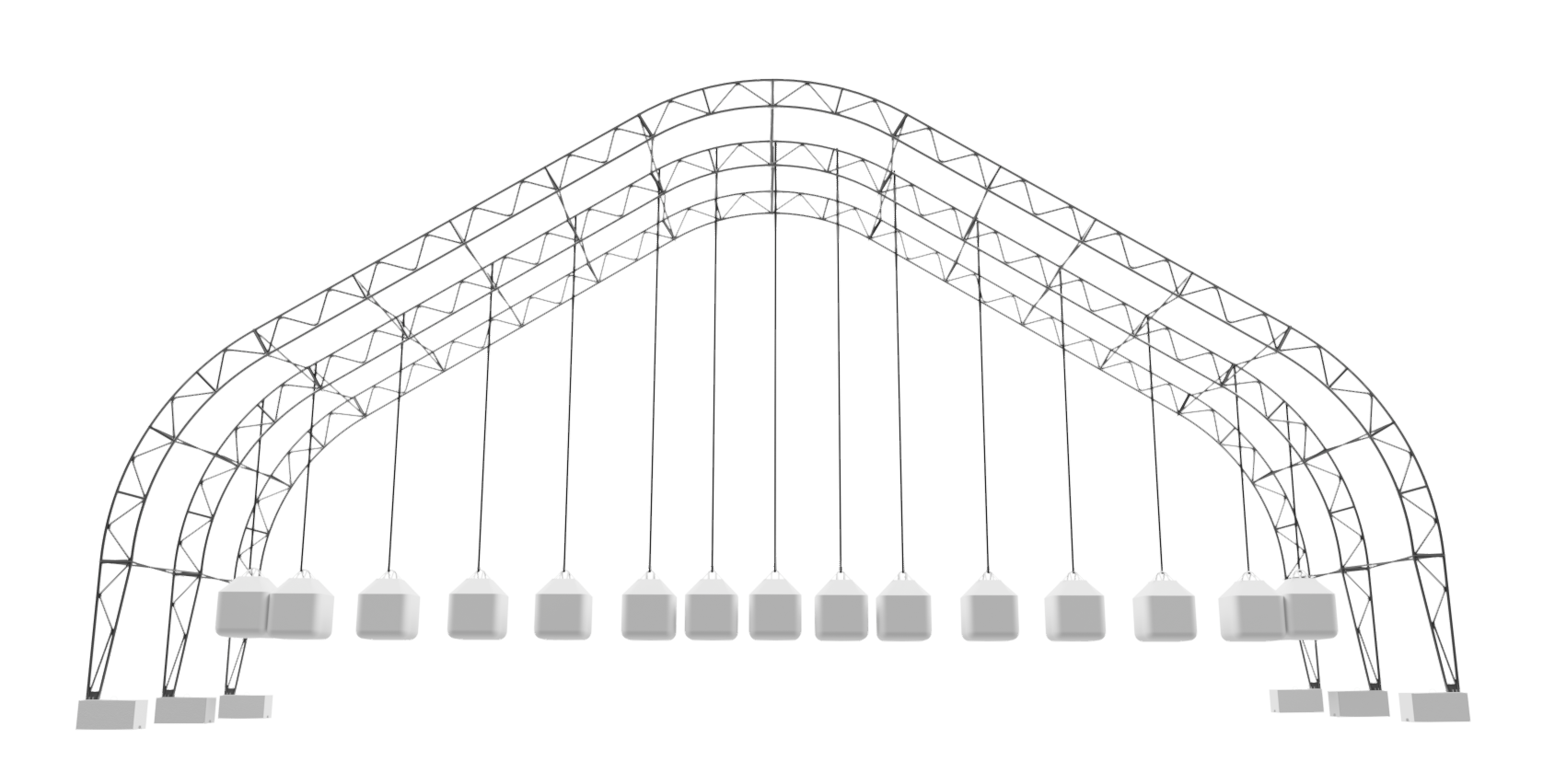

HIGHLY REINFORCED TRUSSED ARCHES - PIN TECHNOLOGY

Our New V FORCE TRUSS SYSTEM is our strongest and most advanced frame system yet. New for 2020 all engineered building models in sizes ranging from 22' - 80' wide will feature this advanced engineered system for maximum strength and maximum manufacturing efficiency, resulting in our Best Fabric Building System on the Market. We focus and invest heavily on innovation in order to meet the demands of our loyal and growing customer base.

ARCH SPAN BUILDINGS developed pin technology and this method is used on all trussed. Vertical pipes also know as pins are fitted between the inner and outer chord of the truss and the saddle joint is entirely welded for maximum strength. Pins are used as breaks between the truss webbing so proper loads can be distributed in high stress areas.